The router plane is definitely the way to go, but no need to buy one if you have a cheapo honing guide lying around...

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Deepening a Truss Rod Channel http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=9412 |

Page 1 of 1 |

| Author: | Brock Poling [ Mon Nov 20, 2006 2:54 pm ] |

| Post subject: | |

I need to deepen a truss rod channel on a finished (carved) neck. After I did my final flattening my truss rod is about 1/64 too tall. Any thoughts about how I can deepen the channel just a smidge? Worst case I can make a sanding stick to do it, but I figure that SOMEONE has bumpped into this problem and solved in in a very easy way. |

|

| Author: | KenMcKay [ Mon Nov 20, 2006 3:02 pm ] |

| Post subject: | |

Find a chisel about the width of the channel and use it as a scraper. If I was just getting dust, I would make a little scraper and put a bur on it. |

|

| Author: | peterm [ Mon Nov 20, 2006 3:09 pm ] |

| Post subject: | |

can you route it? clamp a flat board to one side and use as a guide... |

|

| Author: | old man [ Mon Nov 20, 2006 3:28 pm ] |

| Post subject: | |

I had that problem on my current build, Brock. I did what Ken said. Used a sharp 1/4" chisel as a scraper, and it worked well. Ron |

|

| Author: | A Peebels [ Mon Nov 20, 2006 3:42 pm ] |

| Post subject: | |

I've had to do this a couple of times, and I just used a very sharp 1/4" chisel to lower the bottom. I just pared away at the bottom until I reached the depth that I needed. Al |

|

| Author: | peterm [ Mon Nov 20, 2006 3:50 pm ] |

| Post subject: | |

Only thing I see when using a chisel is there's a possibility of not getting an even depth all the way down the chanel. No biggie but I prefer an even channel to get rod contact all the way through the chanel. |

|

| Author: | Bob Garrish [ Mon Nov 20, 2006 4:13 pm ] |

| Post subject: | |

Router plane, it's the perfect tool for that sort of thing. I don't have one, but it was a good friend of mine when I was with Al Carruth. |

|

| Author: | James Orr [ Mon Nov 20, 2006 4:29 pm ] |

| Post subject: | |

The problem with routing is that if the neck is finished, you'd need to move the neck on top of a router table. It wouldn't be hard if you had a sled made for the neck with the same taper. It wouldn't be hard, but why make a special sled when you can sand it in a few minutes? |

|

| Author: | Robbie O'Brien [ Mon Nov 20, 2006 4:50 pm ] |

| Post subject: | |

If you only need to lower the channel a 64th why not put a file on edge in the channel and file away? You will remove the 64th in no time and it will be flat as well. |

|

| Author: | Rod True [ Mon Nov 20, 2006 7:04 pm ] |

| Post subject: | |

I sort of hate to remind you of this Brock, but didn't something similar as this happen about 8 months ago. Here's your first post on the topic |

|

| Author: | John Watkins [ Mon Nov 20, 2006 10:44 pm ] |

| Post subject: | |

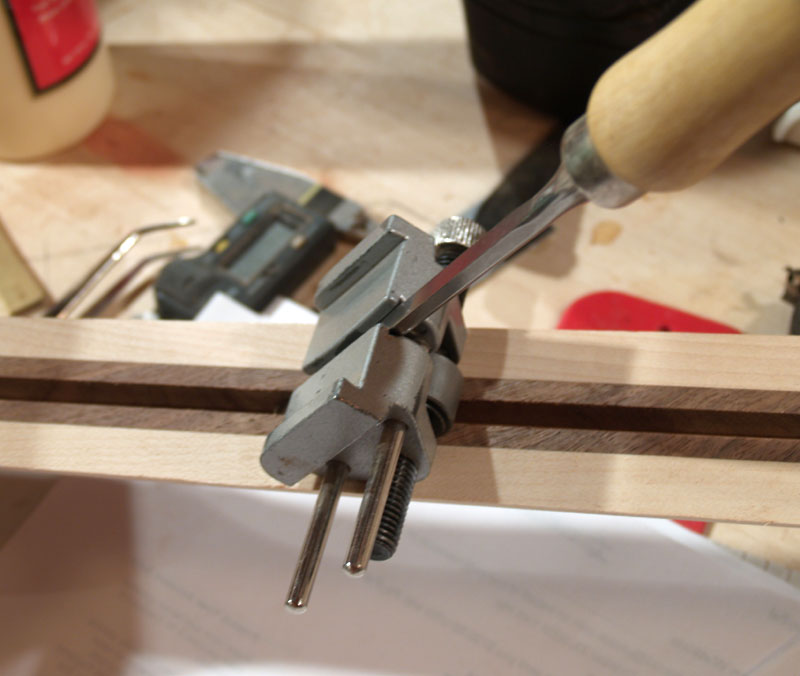

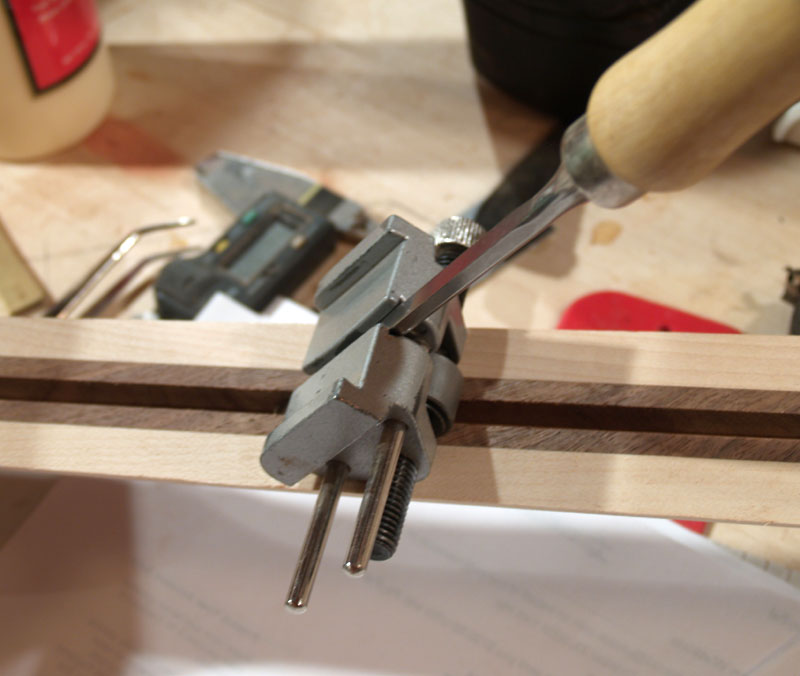

The router plane is definitely the way to go, but no need to buy one if you have a cheapo honing guide lying around...

|

|

| Author: | Serge Poirier [ Mon Nov 20, 2006 11:15 pm ] |

| Post subject: | |

I like Robbie's idea a lot, not too agressive and effective, ask me how i know this!

|

|

| Author: | Brock Poling [ Mon Nov 20, 2006 11:39 pm ] |

| Post subject: | |

[QUOTE=Rod True] I sort of hate to remind you of this Brock, but didn't something similar as this happen about 8 months ago. Here's your first post on the topic[/QUOTE] Last time it was flat, this time it is carved. I have a solution when the neck is still flat... but it won't work on a carved neck. |

|

| Author: | Kim [ Tue Nov 21, 2006 1:06 am ] |

| Post subject: | |

[QUOTE=John Watkins] The router plane is definitely the way to go, but no need to buy one if you have a cheapo honing guide lying around...[/QUOTE] Very clever John, I will remember that one, veeeerrrry clever

Brock, if you make a caul to hold the back of the neck I bet it will come in handy for lots of jobs after this one down the track. If you do not want to go to the trouble, maybe you could pack out your vice with some high density foam rubber and clamp the neck from the side. Another alternative is to proceed ahead and get the tuner holes drilled. Make a flat block caul with some dowels protruding in the same pattern as those in the peghead, you should only need 2. Clamp the caul in a vice or onto a bench and then clamp the heel to support it laterally and you should be set to go with Johns trick,(veeeery clever John) or a 271 router plane, or a scraper as suggested above. Hope this helps Cheers Kim |

|

| Author: | Brock Poling [ Tue Nov 21, 2006 1:16 am ] |

| Post subject: | |

Thanks... These are good ideas. |

|

| Author: | Rod True [ Tue Nov 21, 2006 1:16 am ] |

| Post subject: | |

Ah, ok sorry Brock. |

|

| Author: | Tom Armstrong [ Tue Nov 21, 2006 1:21 am ] |

| Post subject: | |

I just had the same issue and resolved it by free hand routing with a smaller diameter bit., staying away from the channel sides. I cleaned it up with a chisel...the whole process took maybe 10 minutes. Of course you have to be careful freehanding the router but I did not have any difficulty with it and will do it again if the need arises. good luck, Tom Armstrong |

|

| Author: | dgalas [ Tue Nov 21, 2006 4:25 am ] |

| Post subject: | |

I'll second the router plane recommendation. You usually can find them pretty cheap on the 'bay', and once you have one you'll find more uses for it than you thought you might. Wonderful tools. |

|

| Author: | Keith M [ Thu Nov 23, 2006 3:21 am ] |

| Post subject: | |

Brock, I made a wooden base for my lam trimmer and then glued a two inch long strip of wood that just fit in the slot and lined up with the router bit. The wood strip guides the router bit and recutting the channel depth is a very precise and easy. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|